Mechanical Properties

Mechanical properties on tubes such as the breaking strength and the yield stress are important for determining whether a bending device is capable of bending a tube.Stretch of Material Properties

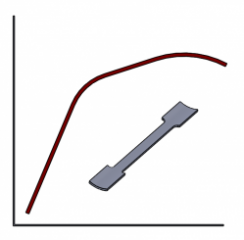

For the bend itself, material elongation is a very important indication. Simply put, this concerns how much the material can be manipulated (bent) before it is damaged. The stretch of the material is collected by the fundamental tensile tests, and it must be given in a percentage. The higher the value, the better the properties of bend.

The calculation for determining the stretch of the tubes

Chemical composition

The chemical composition of the tubes also has an impact on the choice of particular materials such as friction, wear, or lubrication. For more information on the individual combinations of materials see the chapter dedicated to instruments.

How the tubes are made

How the tubes are manufactured determines not only the accuracy of the tube, but also the construction of the tools, and the size and shape of welds. This has a significant impact on the distribution of pressure and the bend. Therefore, where possible, place the weld in neutral positions, when the pressure tends to zero so the weld is not affected by pressure or stretch.