The Physics of Bending

Simply stated, bending can be described as a technological process using a set of tools that manipulates the shape of a tube.

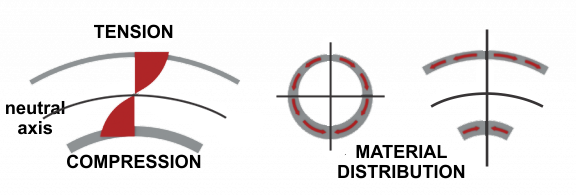

The pulling force on the outer radius of the bend causes the wall of the tube to become thinner, while a pressing force on the inner diameter leads to it becoming wrinkled. Between these layers is a so-called Neutral layer (axis), where forces remains equal to zero.

A permanent bend occurs when the pulling force exceeds the yield stress of the material. At the same time, this force must not exceed the breaking strength of the material (this is also related to the stretch of the material).

The distribution of forces and the position of the neutral layer depends on many factors. Some of these factors include: the parameters and material of the tube, and the machine and its tooling set up. The distribution of the forces has a significant impact on the part being bent. When bending a part with an open cavity, like a tube, it is much more complicated than bending plate metal because there are many more possible defects, which are initiated by the distribution of forces around the bend.

For more information on defects and prevention, see the Basic Tube Bending Defects section.