Basic Tube Bending Defects

Flattening of the cross-section of the tube

Flattening of the cross-section of the tubes is caused by the distribution forces through the bend and can be greatly reduced by using the appropriate inner insert (mandrel) and setting them up properly.

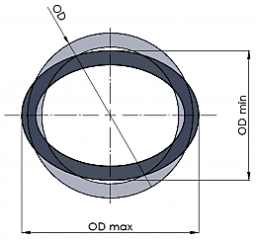

The flattening can be monitored by using the coefficient of ovalness:

![]()

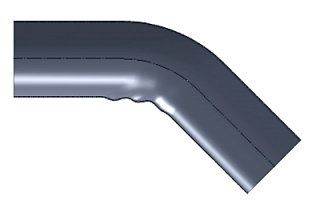

Inner Wall Wrinkles

This is where the stability of the walls is lost on the inner radius of the bend. It is due to pressing forces caused during bending. Reduction or limitation of wrinkling can be achieved by properly setting up the appropriate mandrel and wiper die.

Outer Wall Thinning

The thinning of the walls on the outer side of the radius of the bend naturally occurs when you are bending tubes. However, you can greatly decrease the amount of thinning on the outer radius by selecting the right choice of tools and setting them up properly.

It is very effective to reduce the thinning of the walls with a so-called Booster, which is essentially just extra pressure that pushes on the tube in the direction of the bend and reduces the tension on the inner diameter of the bend.

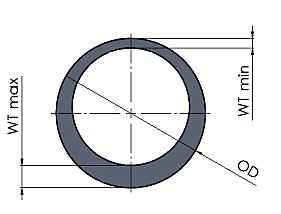

There are many other factors which can lead to the thinning of the walls during a bend. The parameters of the tube bending are crucial (OD, CLR, WT), but there is also a significant impact from the tools and how they are set up. The materials of the tube and the equipment used should also be considered.

The calculation for the thickness of the walls on the outer radius for the bending depends on many relationships. In essence, all are only theoretical and neglect external influences. An example of one of them is below:

![]() or

or ![]()

Springback During Bending

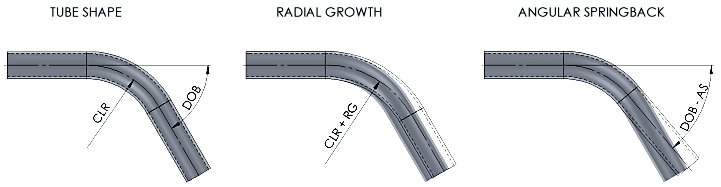

One common defect is the change in the radius of the bend and the change in the angle of the bend after the end of a bend due to springback.

It is necessary of course to differentiate ANGULAR SPRINGBACK from RADIAL GROWTH.

Angular springback

This is how the tube will spring back a few degrees in the direction of the bend when released from the tools. This occurs when it is necessary to bend with a greater angle of bend than is necessary (so-called overbending). The real defect of springback is when the tube is deformed after it returns back.

Radial growth

Sometimes the radius of the bend will grow over the tooling radius as an effect of the springback defect. There will be a significant increase occurring primarily in relatively large radius bends ( "D of bend > 4") and during the bending of incredibly stiff materials. In these cases, it is necessary to reduce the radius of the tools so that they have the required shape after bending.