Mandrel and Wiper Die Selection

The table below is a basic guide for identifying the mandrel type, any necessary number of balls and wiper dies.

|

|

| "D" of bend | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | ||

| Wall Factor | 10 | M1 | M1 | M1 | M1 | P | P | ||

| 15 | M1W | M1W | M1 | M1 | P | P | |||

| 20 | M2W | M2W | M1W | M1 | M1 | M1 | P | ||

| 25 | M3W | M2W | M1W | M1W | M1 | M1 | M1 | ||

| 30 | M3W | M3W | M2W | M2W | M1W | M1 | M1 | M1 | |

| 35 | M3W | M3W | M3W | M2W | M2W | M2W | M1 | M1 | |

| 40 | TW4W | M3W | M3W | M3W | M3W | M3W | M2W | M2 | |

| 45 | TW4W | M3W | M3W | M3W | M3W | M3W | M2W | M2W | |

| 50 | TW4W | TW4W | TW4W | TW4W | M3W | M3W | M2W | M2W | |

| 60 | TW4W | TW4W | TW4W | TW4W | TW4W | M3W | M2W | M2W | |

| 70 | TW5W | TW5W | TW5W | TW5W | TW4W | M3W | M3W | M2W | |

| 80 | TW5W | TW5W | TW5W | TW5W | TW4W | TW4W | M3W | M2W | |

| 90 | TW5W | TW5W | TW5W | TW5W | TW5W | TW4W | M3W | M3W | |

| 100 | UTW8W | TW5W | TW5W | TW5W | TW5W | TW4W | TW4W | TW4W | |

| 125 | UTW8W | TW5W | TW5W | TW5W | TW5W | TW5W | TW4W | TW4W | |

| 150 | UTW8W | UTW8W | UTW8W | UTW8W | TW5W | TW5W | TW5W | TW5W | |

| 175 | UTW10W | UTW8W | UTW8W | UTW8W | UTW6W | TW6W | TW6W | TW6W | |

| 200 | UTW10W | UTW10W | UTW10W | UTW10W | UTW8W | TW9W | TW8W | TW8W | |

| 225 | UTW10W | UTW10W | UTW10W | UTW9W | UTW10W | TW10W | TW10W | ||

| 250 | UTW10W | UTW10W | UTW10W | UTW10W | UTW10W | UTW10W | |||

| 275 | UTW10W | UTW10W | UTW10W | UTW10W | UTW10W | UTW10W | |||

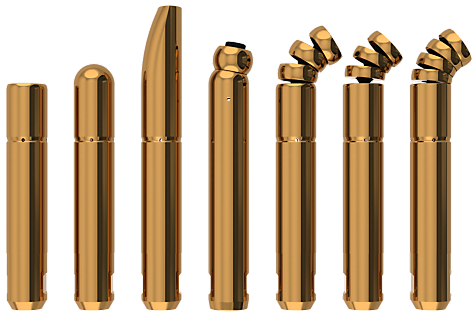

P = Plug mandrel

M = Standard pitch mandrel

TW = Close pitch mandrel

UTW = Ultra close pitch mandrel

# = Number of balls

W = Wiper die required

Example 1: Bending 2.0" od x .065 wall x 3.0" clr

|

|

Example 2: Bending 60mm od x 1.2mm wall x 90.0mm clr

|

|

Example 3: Bending 127mm od x 2mm wall x 170.0mm clr

|

|

It is always recommended to consult with someone on our Sales or Quoting Team for additional information since tool selection is dependent on so many factors.