I/O

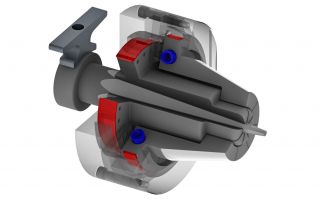

This is a two-function segmented shaping tool I/O. Suitable for reduction and expansion of tube diameters. Complete assembly is composed of external collets, internal fingers, mandrel and barrel in which the individual parts are assembled. This type of tool is the only one, which has fingers and external collets. This means that it is possible to re-inforce the shaped area from the inside or the outside, which gives much greater variability in this type of tool. From the range of segmented shaping tools, the I/O gives us the best quality from the point of view of tube shaping.

Complete assembly is composed of external collets, internal fingers, mandrel and barrel in which the individual parts are assembled. This type of tool is the only one, which has fingers and external collets. This means that it is possible to re-inforce the shaped area from the inside or the outside, which gives much greater variability in this type of tool. From the range of segmented shaping tools, the I/O gives us the best quality from the point of view of tube shaping.

I/O End Forming Tool Parts

Arbor

This component is inserted to the machine as an independent unit. The movement of the machine pushes the mandrel into the fixed area of the expanding fingers. The leads to the expansion and calibration of the tubes.

From a production perspective this product come in two variants depending on the outer diameter of the tubes, 6- or 8-segmented with different angles on the fixed area.

Fingers

The movement of the mandrel cause the segments to be expanded to the required diameter of the tube. The mandrel is inserted through the correct fixed section on the individual segments of the inner fingers, which then apply a force to the inner side of the shaped area.

From a production perspective this product comes in two variants depending on the outer diameter of the tubes.

Jaws

To reduce the tube into required shape we use cone-shaped jaws inside a cone-shaped outer section. Using pistons we move the barrel into which the jaw is inserted or we move the front part of the shaping machine with the fixed cone.

The jaws are manufactured in three options 2.75 STD, HD, 3.125 (in inches). When changing the jaws type it is necessary to also changed the fixed cone of the machine.

Barrel

The barrel is made up of three parts, into which are inserted a mandrel and collets. The barrel is fixed into the frame of the machine and using the pistons we can move the fixed cone towards the barrel. In this way the collet is closed to the required diameter. The width of the closing surface of the barrel is 70 mm.